Craft brands are ditching paper labels faster than ever — and someone has to print directly on the glass. There is an emerging market for glass bottle printing as a niche business. Additionally, demand for product customization and personalization is increasing.

So, let’s explore how you can start your own glass bottle printing business.

Benefits of opening a glass bottle printing business

- The glass bottle printing industry is growing. The following factors contribute to this increase

- Breweries aren’t the only ones that produce them. Other small-scale producers also use direct-printed bottles to protect their brands.

- Label-printed bottles reduce paper waste. They end the need for a traditional label on each product package. They end the need for a conventional label on each product package. Thus, one of their customer segments includes people who appreciate environmental conservation.

- Consumers may perceive printed bottles as superior quality. Your business model can tap into this luxury market.

- A direct-printed bottle costs more than one without print but sells better. Thus, this will enable you to break even quickly before earning a profit.

- You can design bottles in almost any design they want. For example, you may have a couple of glass bottles with a logo drawn on them, or you may request a sophisticated drawing.

- This area is less crowded than many others. It means that there are opportunities for new entrepreneurs to take over and build a real business.

- Most organizations need repeated orders for labeling or packaging materials. Customers are likely to reorder labels for bottles that have already been printed because labels are reusable.

Let’s Begin: Here’s What You Need to Launch Your Business:

Market Mavens:

Before taking off, ask yourself who needs these fancy printed bottles. Are breweries coming up with their own unique craft beers? Wineries whose bottles should stand out on shelves? Or perhaps small businesses looking for custom-made gifts and party favors?

- Have conversations with potential buyers

- Review some industry statistics around you.

By doing so, you can understand what is currently trending in the market.

The Competition Check:

What are other companies printing on their glasses? Are there any gaps in their market where you could specialize? For example, you could specialize in small-batch printing for local businesses. All you need to do is provide unique printing techniques that make yours stand out from competitors’. Understanding what others offer will help you develop a winning plan.

Numbers Game

Beginning by creating wonderful designs isn’t enough! Study the financial aspect of starting this business.

- How much for the machinery?

- What do you need legal-wise?

- Make sure you do a cash flow, assessing whether your aspiration is realistic and when you expect to make profits. Also, keep in mind the rent money they will have to pay, salaries for the employees, and even advertising costs, among other things.

Planning is Key

To start things off, consider these aspects when planning for your printing business:

Are you interested in short runs with custom design? Do you want to cater to small businesses and events? Or large-scale production targeting high-volume brand orders?

It’s A Business Plan.

- Vision statement

- Identify your target market

- How you will promote your brand

Licenses and Permits

To operate legally, you should obtain specific permits and licenses. Always remember that your local and state authorities should approve these:

- Your business operations

- Health and safety standards

- Environmental laws

Invest in the Right Tools.

In printing glass bottles, the type of machines that you use matters a lot.

Two methods are used in printing glass bottles: screen printing and digital printing. Each method uses a unique set of machines and has its own advantages.

Screen Printing

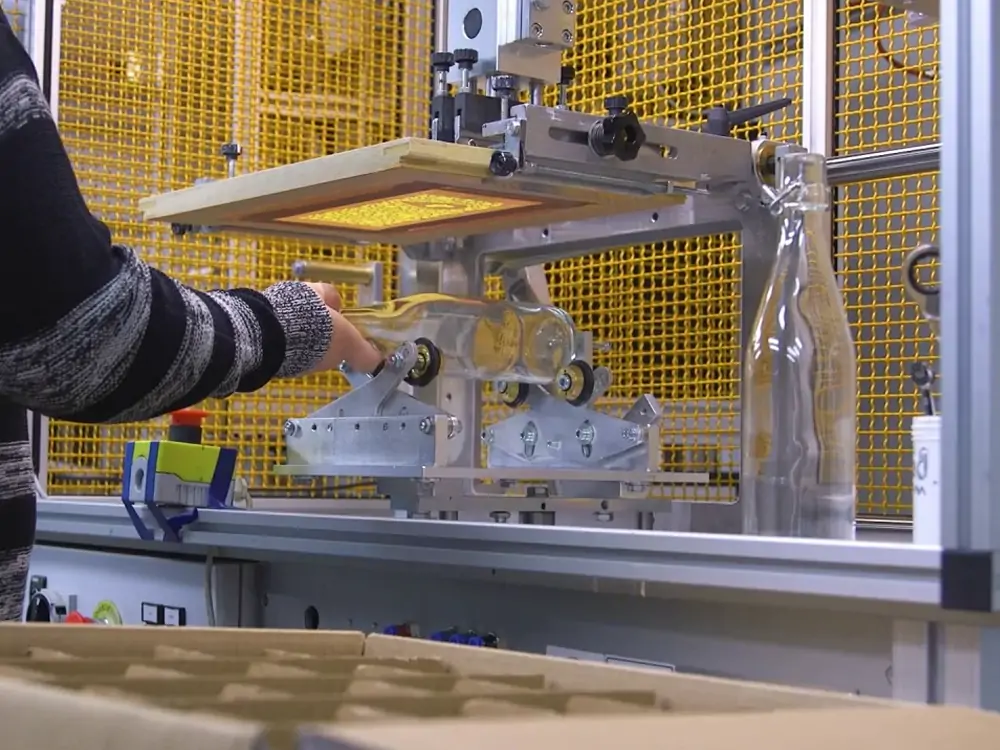

Screen printing is the most commonly used printing method for glass bottles. During screen printing, a machine pushes ink through a stencil directly on the bottle.

This stencil is usually a mesh screen.

To print using this method, you’ll need:

Printing Press

It’s like having a giant stamp pad pressing down on the screen, delivering ink to the bottle.

Carousel

It’s a machine with many sections where you can place bottles. While one is being printed, others can dry up on the rack.

Drying System

After printing your bottles, dry them in an oven or another heat source.

After printing the bottles, dry them. One possible way is for them to pass through a conveyor belt in a heating device.

Digital Printing:

This new technique relies on inkjet printers. Only inkjet printers can print on the bottle.

You’ll need the following essentials for this technique:

Inkjet Printer:

These modern gadgets eject the colorant onto the bottles’ surfaces. They’re good for your bottling business but expensive for home use.

Curing System:

Exposing printed material to UV radiation ensures its stability after drying. You may buy a lamp to dry the ink faster.

How to Choose the Best Equipment:

Start with your budget:

In most cases, screen printing machines are cheaper than digital ones.

Consider the volume of output.

If you are into large-volume screen printing, you can invest in a carousel system.

Consider the complexity of the design:

Digital printing offers more options for creating complex patterns.

Get guidance from professionals:

Feel free to seek help from printing equipment manufacturers or experienced printers. They can help you select the right machine for your specific requirements.

Here’s how you can build your market presence:

Find suppliers you can trust:

Consider attending industry trade shows or searching online directories. Inquire about the lowest possible order quantities (MOQs), lead times, and other details.

This information is essential. Especially when you negotiate with them about price and other issues. Remember, good relationships with your suppliers are everything.

Get partners:

You can look for businesses that complement yours. Or, if you operate on your own, partnering with an artist might attract more customers. Teaming up with others enables diversification of service provision. You’ll be able to reach new clients, too. It is possible to bring in new customers even when carrying out your business alone.

Associations:

Join glass printing or packaging industry associations or virtual forums. These will connect you with other experts, and you can learn while sharing your knowledge. Seeking to learn more about new printing techniques and equipment.

Why You Should Become a Resource

Also, give something back; don’t take everything from your potential clients. You can start by offering them some free consultation hours. Even if they may only use them to discuss design ideas, they can skim through websites where people often ask these types of questions

Reddit’s subreddit on graphic design and industry-specific forum sections are great platforms.

Networking Events

Attend industry conferences, trade fairs, and local business networking events. These are the ideal places to meet prospective customers, suppliers, or even partners. Remember to always have your business cards with you at such gatherings. Also, ensure that you rehearse your elevator pitch. Prepare a short and clear explanation of what your company offers and who its customers are.

Next step: grab a six-pack from your local brewery this weekend and ask who prints their bottles.