Over 60% of packaging in the cosmetics and beverages industries uses some screen printing. That is a significant portion—and it is growing.

However, the shape of your product is a primary factor in deciding the printing result. If you are printing on tubes, panels, or bottles, the proper method can save time, reduce costs, and enhance print quality. Using the wrong technique can lead to smudging, poor sticking, or high failure rates.

This guide explains the main differences between cylindrical and flat silk screen printing. You will be able to identify the strengths and weaknesses of different methods, as well as suitable machines for your production needs.

Moreover, you will also get helpful ideas whether you are a maker, a product designer, or an engineer. With this guide, you will be able to make better choices and smarter printing decisions.

Basics of Screen Printing

What Is Silk Screen Printing?

Like many other methods, silk screen printing became part of technology a thousand years ago. It was first done with silk mesh, but today it uses a stronger fake mesh like polyester.

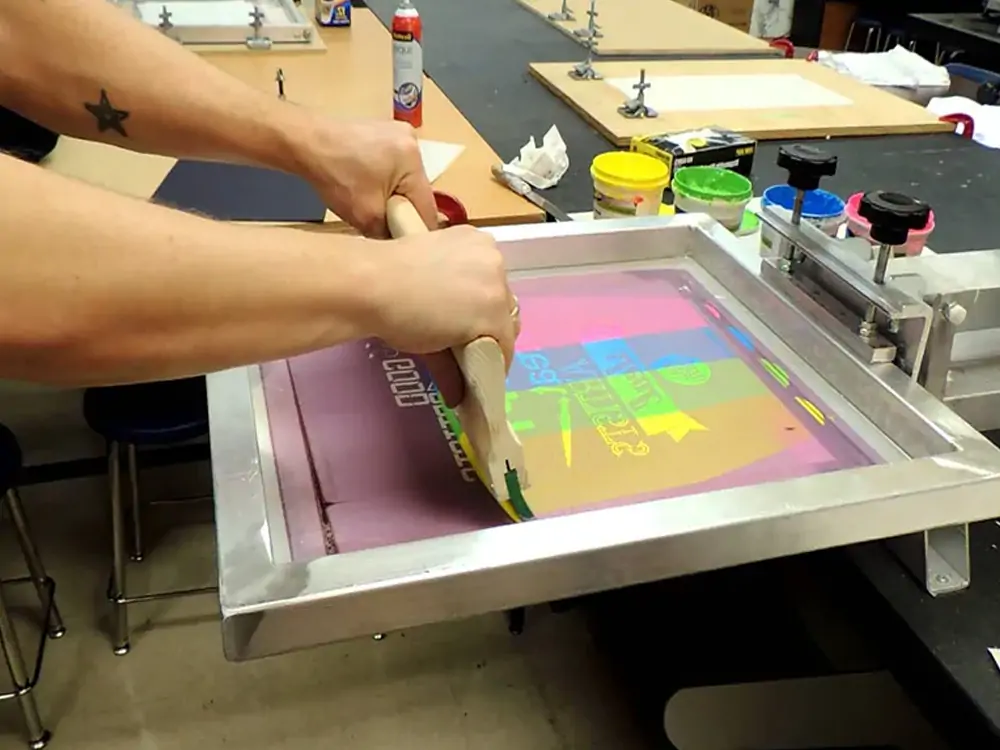

The basics are quite simple:

- A stencil is placed over the mesh

- Ink is added

- A squeegee is used to push ink through the open areas onto the chosen surface.

This method allows you to control the amount of ink used with precision. It is trusted and flexible. Different types of ink can be picked depending on the material used. Solvent-based inks are good for metal and plastic surfaces.

UV inks are suitable for fast and detailed work because they dry quickly with the aid of UV light. Eco-friendly, water-based inks are best suited for use on soft materials, such as paper or cardboard.

Types of Substrates

Screen printing is not the same for every item, and the shape of the item you are printing is also essential.

| Type of Item | Common Materials | Uses |

|---|---|---|

| Cylindrical | Glass, plastic, and metal | Cans, bottles, and tumblers |

| Flat | Steel, PVC, and acrylic | Flat boards, panels, and signs |

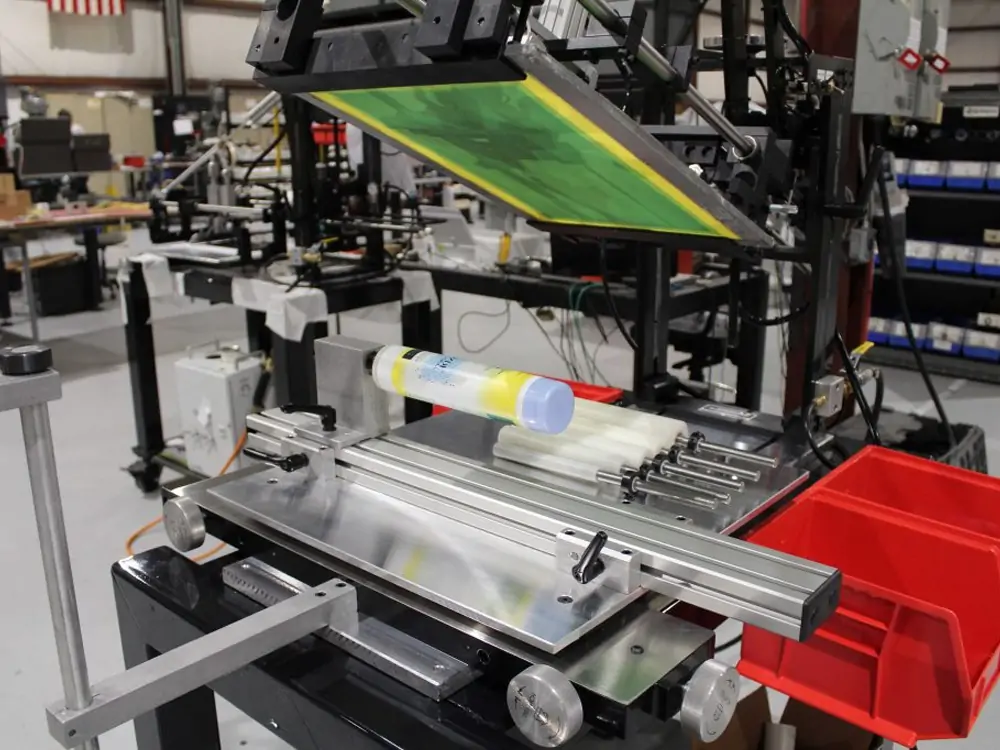

Cylindrical Silk Screen Printing

This prints images on items with round and curved shapes. It uses turning holders or tools as a base and a rotary fixture for the item, which could be a tube, mug, or bottle.

The substrate rotates beneath a stationary screen and squeegee, ensuring distortion-free 360° printing. This match in movement allows a smooth ink layer and even coverage. So, you can clearly and sharply print images without distortion.

Suitable Applications

- It is ideal to decorate drinking tumblers, mugs, and bottles.

- In the beauty industry, it is widely used to label glass jars and decorate plastic tubes.

- This method is commonly used in the industry for marking round parts, such as metal tubes, tool handles, and other machine components.

Equipment Used

- Cylindrical printing is done on half-automatic and fully automatic machines.

- New models have servo motors for better control and have turning tables for fast work.

- Many systems feature flame or heat treatment units to enhance ink adhesion.

Technical Considerations

- Marking curved surfaces requires careful setup and placement, especially when printing in multiple colors.

- Automatic machines can print 1,200 to 1,800 pieces per hour.

- However, color and ink sticking to the curves is more challenging.

- Correct setup and surface treatment are needed.

Flat Screen Printing

Flat screen printing is suitable for smooth, not curved, surfaces. It uses a fixed bed to hold the item in place. A straight squeegee pushes ink through the screen and stencil onto the surface.

During the printing process, since nothing moves, you have great control of ink flow and thickness.

This method works best for items without curves. For products with flat surfaces, flat screen printing gives clean, even results.

Suitable Applications

Flat-screen printing can be applied across various industries.

- For example, it works well in making signs, flat plastic sheets, and cardboard boxes.

- In the automotive industry, it often helps to print on control panels and other dashboard components.

- You can also use it to mark PCBs and small electronic parts that need fine details.

Equipment Used

- Flat screen printers come in three types. You can choose manual, semi-automatic, or fully automatic ones.

- If you plan to print on thin or soft materials, it is recommended to use a vacuum bed. It holds the material flat and still.

- For large printing jobs, conveyor systems are helpful. They move the material smoothly through both printing and drying steps. This saves time and reduces errors.

Technical Considerations

- Flat screen printing gives you better control of ink.

- You can get cleaner lines and even color. This is because the surface stays still during printing.

- Additionally, multi-color prints are easier to align correctly. Nothing moves, so you get better alignment.

- However, keep one thing in mind. You can only use this method for flat or slightly curved surfaces.

- If your product has a complex shape, this method won’t work. You’ll need another solution.

- Still, for flat items, this method offers great speed, good accuracy, and consistent quality.

Side-by-Side Comparison Table

| Feature | Cylindrical Screen Printing | Flat Screen Printing |

| Surface Type | Curved or Round | Flat |

| Machine Complexity | High (spinning parts) | Medium |

| Speed (Automatic) | 1200–1800 pcs/hr | 400–1000 pcs/hr |

| Alignment Accuracy | Medium (less accurate on curves) | High (stable surface) |

| Ink Thickness Control | Medium | High |

| Setup Time | Longer for multi-color work | Shorter, especially single-color |

| Industries Used In | Cosmetics, Medicine, Drinks | Electronics, Signs, Packaging |

| Multi-color Accuracy | Lower (due to rotation) | Higher (fixed surface) |

Factors to Consider Before Choosing

When choosing between the two, keep these points in mind:

Product Geometry

First, look at your product’s shape. Is it flat or round?

Flat items, such as signs or panels, work best with flat printers.

For bottles, jars, or tubes, go with cylindrical printing.

Do you have items with unusual curves or uneven shapes? In that case, standard tools may not work. You might need custom equipment or a mix of methods.

Volume of Production

Next, think about how many items you need to print.

Flat-screen printers are ideal for printing large batches of sheets or boards.

However, if you’re printing thousands of round items, such as bottles or tubes, cylindrical printers are more efficient. They also support more automation.

Print Resolution & Detail

Need high detail and sharp edges? Then flat printing is your best bet.

The still surface helps prevent ink smearing. It also keeps lines sharp and colors clear.

Cylindrical printing may lead to slight ink spreading. It’s harder to keep mesh tight on curved surfaces.

Durability Requirements

Think about how long the print needs to last.

Flat surfaces are easier to work with. You can apply more ink and let it dry properly. This helps the print last longer.

Curved items may require special surface treatment to ensure the ink adheres well.

Machine Cost & ROI

Cylindrical printers cost more. They have rotating parts and advanced controls.

Flat printers are cheaper. You can use them on a wide range of products.

If you’re on a budget, go with flat printers. But always think about the return on your investment.

Use Cases

Cylindrical Printing Case Study

One well-known cosmetics brand utilizes rotary printing daily. They print over 10,000 lipstick tubes daily. The system handles full-color prints with 360-degree coverage.

Fast UV drying keeps the ink bright and long-lasting. The rotary setup ensures the prints line up correctly, even at high speed. This setup is ideal if you need to print many round items quickly and with good quality.

Flat Printing Case Study

An electronics maker screen-prints labels on flat device covers. For accuracy, they use fixed flatbeds. To stop movement, they use vacuum holding—especially for thin PVC sheets. This setup makes sure prints are sharp and easy to read. For exact jobs like yours, flat printing with vacuum support works best.

Advanced Tips and Techniques

Enhancing Adhesion

Start with surface cleaning. Raise energy with flame, plasma, or corona treatment. These steps help with ink sticking, especially on polypropylene. Match ink with material. Metal things need metal inks. Plastics need plastic inks. Skipping this rule has effects.

Reducing Downtime

Keep things smooth in your workflow. For round printers, use quick-change tools. This reduces setup time between batches. For flat printing, your screens should be pre-set. Jigs should be used to secure screens in place, saving time and reducing alignment mistakes.

Multi-Color Setup Optimization

For round jobs, use optical sensors and servo-controlled tools. These color matching systems get exact alignment for each color layer. For flat printing, you should add fine-tuning units to your screens. These help adjust screens to microscopic accuracy.

Ink Type Selection Guide

| Ink Type | Best For | Curing Method | Notes |

|---|---|---|---|

| UV Ink | Plastic, Glass | UV Light | Dries fast, very strong |

| Solvent-Based | Metal, Treated Plastics | Air/Heat | Sticks well, strong |

| Water-Based | Cardboard, Eco Materials | Heat | Earth-friendly, not very strong |

When To Combine Both Techniques

Crossover printing, also known as mixed design printing, combines flat and round printing techniques. For example, electronics with flat screens and round knobs. Both methods cover all surfaces. In packaging, flat labels are used while printing directly on tubes in one go.

For best results, connect both printers with an inline belt. Match your screen setup, drying, and curing steps. These steps enable smooth changes while maintaining the same high quality throughout the prints.

Conclusion

When choosing between flat and round screen printing, it depends on the item’s shape and design. If you print on flat panels, tubes, or bottles, the method you use matters. It can help you save time, cut waste, and improve the print quality. Over 60 percent of packaging screen printing used in cosmetics, beverages, and other products is experiencing rapid growth.

For the best sharp detail and easy alignment on flat surfaces, use flat printing. Round items with full-wrap designs can be produced by high-speed round printing. Therefore, examining the product closely is crucial for quantity, materials, and printing goals. Select the method that best suits your workflow and yields high-quality, consistent results.

Want to improve your printing processes? Make your move today by choosing the right screen printing method and improving quality, speed, and profits.