Introduction:

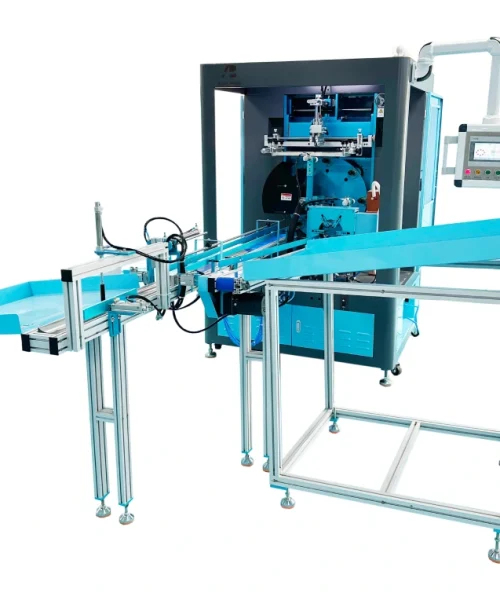

AP-600 Semi auto round screen printing machine is a well designed and versatile round screen printing machine.

The AP-600 screen bottle printer can screen print on glass bottles, plastic water bottles, cosmetic tubes, aluminum water bottles, drum sticks, glass pipettes, etc.

The AP-600 features quick & simple tooling changeovers, precise mechanical registration & conveniently all controls are on the front panel, making the AP-600 the perfect all around universal screen printing press.

Features of Semi Auto Round Screen Printing Machine:

Pneumatic controlled with shock absorbers

Microprocessor controlled – PCB

Vertical part lift with height adjustment

Print stroke controlled with rodless cylinder

X/Y/R positioning ware-mounting table

Linear ball bearings on hardened shafts

Squeegee tilt, skew, and height adjustable

Screen frame angle & tilt adjustable

Synchronized bottle inflation system with regulator

Regulated squeegee pressure with pressure gauge

Floor levelers & casters

Foot switch controlled

Specifications of Semi Auto Round Screen Printing Machine:

| Model No.: | AP-600 |

| Drive System: | Pneumatic |

| Frame Up/Down Stroke: | 100mm (3.94″) |

| Maximum Print Area Round: Maximum Print Area Oval: |

180mm (7.08″) Ø 620mm (24.40″) Arc Length |

| Working Table Size: | 250 x 700mm (9.84″ x 27.56″) |

| Table Adjustment: | X,Y ± 15mm / θ 15 ° |

| Maximum Screen Frame Size: | 400 x 800mm (15.75″ x 31.50″) |

| Screen Frame Thickness: | 18 – 25mm (.71″ – .98″) |

| Squeegee Angle: | 0-15° |

| Printing Cycle Speed: | 960 cycles/hr |

| Squeegee Speed: | 16/min |

| Squeegee Pressure: | 2 – 4 Bar |

| Electric Source: | 110V/220V 50-60Hz 50W |

| Air Pressure Input: | 80 psi |

| Air Consumption: | 0.7 L/cycle |

| Net Weight: | 170 kg (374.79 lbs) |

| Gross Weight: | 260 kg (573.20 lbs) |

| Dimensions (L x W x H): | 1,130 x 750 x 1,350mm (44.49″ x 29.53″ x 53.15″) |

| Crate Dimensions: | 1,250 x 940 x 1,460mm (49.21″ x 37″ x 57.48″) |

Reviews

There are no reviews yet.