Oval bottle printing comes with unique challenges. It can be very tricky for you to align its curved surface. That’s why manual methods do not yield consistent results. Automatic screen printing machines resolve such difficulties with accuracy, speed, and dependability.

When you want perfect prints, the best thing to do is invest in the best machine. Let’s discuss how to achieve ideal printing on oval bottles and the challenges along with it.

Why Printing on Oval Bottles Is Difficult

Mainly for two reasons:

- Oval bottles have an uneven curvature.

- It’s challenging to keep uniform contact and pressure throughout the printing process.

Typical Troubles with Manual or Semi-Automatic Printing on Oval Bottles:

-

Ink smudging and registration problems

Manual printing is prone to smudging. It is challenging to apply pressure across the entire surface of the bottle. That’s why it isn’t easy to match multi-color applications.

-

Production Speed and Waste

Manual printing methods are slow and require placing each bottle by hand. This reduces production output, increases labor costs, and makes the process inefficient.

-

Operator Fatigue

Operator fatigue affects the quality of print. Manual printing has a high learning curve, and new operators must consider training.

Suppose you are looking for a machine that delivers flawless results. The Auromatik’s high-performance machine for oval printing does disappoint you.

-

Misalignment and Irregular Printing

- Positioning Problems

One of the leading causes of misalignment is the shape of the bottle. Oval bottles require fixtures that accommodate multiple axes of rotation. - Screen and Squeegee Issues

Must have the right screen tension. If the level of tension is high, the screen will be unable to adjust to curves. - Environmental Factors

Low-energy plastics do not adhere to inks without proper treatment. Temperature changes also influence the consistency of prints.

Key Technologies That Solve Oval Bottle Printing Challenges

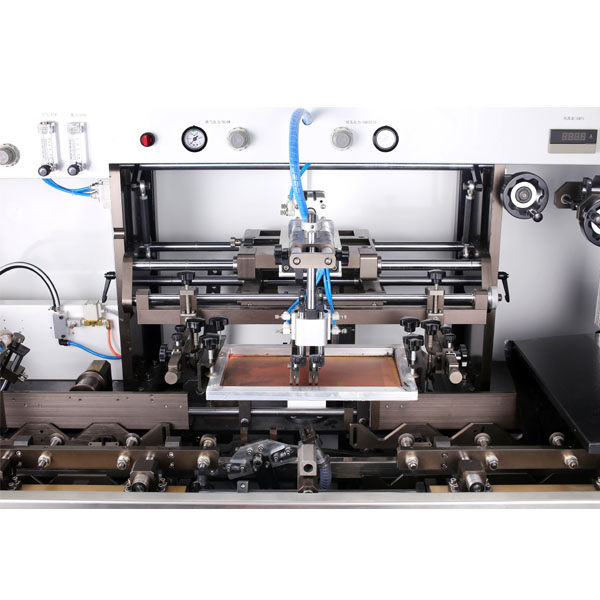

1- Servo Motor Control

Servo motors deliver unmatched precision and control. These motors provide exact positioning capabilities. They move in tiny increments that human hands can’t match. Servo systems adjust for each bottle’s orientation. They detect exact positions and make real-time corrections. Production speed increases while quality improves. Watch this demonstration video to see servo control in action.

2- Vision Systems

CCD cameras add another precision layer. Cameras capture the positions of bottles before printing begins. They rotate bottles during the printing process.

3- Control and Curing Systems

PLC systems coordinate all components. PLCs ensure every movement happens in perfect sequence. They check sensors throughout the printing process. UV curing systems ensure immediate ink setting. Ink cures after bottle application. This thing prevents smudging and allows immediate handling. Similar technology is in automatic UV bottle machines.

4- Pressure Control

Pneumatic systems maintain a consistent squeegee force. Pressure adjusts based on bottle curvature. High points receive less pressure than low points. Touch screen interfaces make operation simple. Operators adjust all parameters from single control panels.

How Automatic Screen Printing Machines Ensure Precise Positioning and Consistent Quality

Positioning Technology:

Automatic systems use indexed positioning for every bottle. Each bottle stops at the same spot. Your curved bottle screen printing machine maintains micron-level accuracy. Positioning systems work within 0.01mm tolerances. This system’s precision is impossible with human operators.

Multi-Axis Control:

Multi-axis control allows for the simultaneous handling of complex bottles. Systems rotate and lift. Your high-speed oval bottle printing system maintains quality at impressive speeds. Automated feeds bring bottles to printing stations.

Quality Control:

Quality inspection happens in real-time during production. Vision systems check each print immediately after application. The oval bottle screen printer uses recipe-based programming. You save all settings for each specific design. Switching products takes seconds, not hours.

Precision Features:

Too much pressure across the print area. Machines check and adjust pressure hundreds of times per second. Registration between many colors becomes precise. Machines reference the same positioning points for each color. Multi-color designs align every single time.

Achieving High-Speed, Stable Printing with Servo Control and Custom Fixtures

1- Servo Benefits:

Servo motors cut the jerky movements of traditional drives. They speed up and decelerate at each station. Gentle handling prevents bottle shifting during transport. Speed adjustments happen with servo control. You can slow down for complex prints or speed up for simple ones. Machines optimize cycle times for each specific job.

2- Custom Fixtures:

Custom fixtures for specific oval bottle shapes are critical. Generic fixtures create gaps where bottles don’t make complete contact. Custom designs support bottles at optimal points. Fixtures must grip without leaving marks. Special soft-touch contact points hold bottles in place. Bottles emerge from printing looking pristine.

3- Speed Features:

Rotary indexing with servo control allows continuous motion printing. Bottles move through stations without stopping completely. This process increases production speed and efficiency. Quick-change fixture systems reduce setup time. Your screen printing on oval bottles becomes profitable at any volume. Servo systems maintain perfect speed synchronization across all axes.

4- Motion Control

Acceleration profiles prevent bottle bounce during movement. Machines avoid inertial effects completely. Position feedback loops run during operation. Encoders on servo motors report exact positions. Controllers compare the actual position to the desired position. Corrections happen in real-time.

Improved Efficiency in Oval Bottle Printing Production

The Challenge Our customers Face:

A cosmetics company faced ongoing issues with printing on oval bottles. Labor costs consumed 40% of their printing budget. Customer complaints about inconsistent quality were increasing every month.

The Solution We Provide:

They invested in an automatic screen printing machine for oval bottles. The machine featured servo control and custom-designed fixtures. Implementation took two weeks, including operator training and familiarization. Rejection rates dropped from 15% to under 2% immediately. That’s a 400% improvement with the same operators.

Results Achieved:

Labor costs as a percentage dropped from 40% to 12%. The machine required minimal operator intervention during runs. Color registration improved to within 0.5mm across all colors. Customer complaints about print quality disappeared completely. Setup time for new designs decreased from 4 hours to 20 minutes. Recipe-based programming made changeovers fast and efficient.

Financial Impact:

Savings covered 60% of the cost. Increased capacity generated new revenue streams. They took on contract printing work for other brands. Energy consumption per bottle decreased by 35%. Maintenance costs were 40% lower than those of the old equipment. Operator satisfaction increased after installation.

Choosing the Right Automatic Screen Printing Solution for Oval Bottles

Oval bottle printing doesn’t have to be a struggle. The right equipment transforms challenges into competitive advantages. Your choice of printing system impacts your bottom line.

There are some critical features when you are buying:

Servo control should be a non-negotiable need. This technology provides the precision essential for quality printing. Custom fixtures designed for your specific bottles are crucial. Don’t settle for adjustable generic fixtures. Integration capabilities are critical for future line expansion. Select systems that connect with upstream and downstream equipment.

The cheapest machine often becomes the most expensive over time. Choose vendors with proven experience in oval bottle printing applications. They should offer comprehensive training and responsive support. Scalability ensures that your investment grows with your business.

Don’t let misaligned prints damage your brand image or profitability.

The automatic printing machine affects quality, cost, speed, and customer satisfaction. Ready to drop your oval bottle printing frustrations? Auromatik provides comprehensive solutions to all bottle printing needs. Your brand deserves packaging reflecting your quality standards. Modern printing technology makes perfection achievable and affordable. Don’t let outdated equipment hold your business back any longer.