Choosing the right bucket printer is a significant investment for your business. Having the proper machine is essential in manufacturing and retail. This article will help you understand what to look for when deciding on a bucket printer.

Key Features to Consider

1. Print Quality and Resolution

Print quality is of utmost importance. A high-quality print ensures every detail of your design is sharp and clear, which is crucial for brand perception and regulatory compliance.

2. Speed and Efficiency

Speed is just as important as print quality. Higher speeds boost productivity and are essential to fulfill tight production schedules.

3. Versatility and Flexibility

A machine that can handle a wide range of bucket sizes and shapes, permitting flexibility in production. Look for machines that support a couple of printing methods and functions.

4. Ease of Use and Maintenance

Easy-to-use equipment reduces training time and operational errors. In addition, remember the need for maintenance. Machines with replaceable components, effortlessly accessible parts, and with easy maintenance procedures are preferred.

5. Cost and Budget Considerations

While high-end devices provide more, they are more expensive. Balance your price range to find the most cost-effective choice.

Evaluating Your Business Needs for the Right Bucket Printing Machine

If you have a business that uses sealed buckets, consider getting a bucket printer. So how do you choose the right one? Let’s look at some key points to help you decide.

Understanding Your Business Needs

First, determine how many printed buckets you need per day, week, or month.

1. Production Volume

Determine how many lots you produce to determine which device you need. Large-scale manufacturing requires high-speed automation, while manual or semi-automatic machines can control less complex processes.

2. Customization Requirements

If your business requires a variety of custom prints, look for machines that offer flexibility and versatility.

Comparing Different Technologies

When choosing the right bucket printer, different technologies must be considered. Each technology has its advantages. This article will help you examine those technologies and achieve great results for your business.

Comparing Costs

When comparing technologies, cost must be considered. Some methods are expensive initially but may be less costly in the long run. Others may be cheaper upfront, but cost more in maintenance and supplies.

Digital printing

Digital printing sends your artwork directly from the computer to the bucket — no plates, no screens. It is perfect for small—to medium-sized businesses.

Cost:

- Planning: Very little

- Each print: Medium

- Pros: small batch, rapid turnaround, and variable information printing (such as individual items).

Digital printing is more cost-effective and faster, as it avoids the setup charges of traditional printing methods.

Screen printing

Screen printing involves creating a stencil (or screen) and using it to apply an ink layer to the floor of the print.

Cost:

- Setup: High (due to display practice).

- Per-unit cost: Low (per unit when done in quantity).

- Pros: Large batches, colourful colourings, simple shapes.

Although setup costs are high, per-unit costs drop dramatically at high volumes.

360° Digital UV Printing

UV light is used to cure or dry the ink as it is printed, producing excessive, colorful colorations.

Cost:

- Planning: Medium

- For every print: Medium to excessive

- The excellent: High-quality print, durable prints on plastic buckets, and unique features.

UV printing produces high-quality, durable prints; however, it can be significantly more expensive than other strategies.

Quality and Speed

Consider the quality and speed of each printing method. Some technologies offer high-quality printing, while others are faster. Decide what is most important to your business.

Digital Printing:

In today’s fast-paced world, the need for excellent and rapid printing solutions is greater than ever. Digital printing has emerged as the superior option, presenting first-class quality and speed. Here’s a closer look at special printing methods and how they work.

Screen printing

Screen printing is a traditional method that is still well known to many. It uses it to create a stencil (or display screen) and puts a little ink on the print.

- Quality: Screen printing is colourful and durable. Ideal for huge, bold photographs.

- Speed: While installing the display screen may be time-consuming, once it has everything ready, the process is quite speedy, especially for bulk orders.

UV Printing

UV printing uses ultraviolet light to treat or dry the ink at some point during printing. This technique is gaining a reputation due to its versatility and productivity.

- Quality: UV printing produces sharp, vibrant photographs and can be used on a variety of surfaces, including glass, metal, and plastic.

- Speed: The instantaneous drying process enables ultraviolet printing to be rapid, making it best for large-volume orders

Ease of Use

Digital Printing

Digital printing is a current form of publishing that is fantastically clean to use. It involves sending a digital file to the printer immediately. This technique is perfect for quick runs and allows for brief flexibility and changes. It removes the need for plates and canvas, making it ideal for on-call printing.

Screen Printing

Screen printing is a traditional method that involves growing a stencil (or screen) and using it to apply ink to the floor of the print. This approach is specifically appropriate for bulk printing t-shirts and posters. Although the setup may be a bit complex, once it is set up, it is simple to use and produces charming text.

UV Printing

UV light is used to dry or cure the ink during ultraviolet light printing. This method can be very speedy and produces vibrant and dense prints. It is ideal for printing on a wide range of materials, including plastic, glass, and steel. UV printers are easy to work with.

Types of Bucket Printing Machines

When choosing a bucket printer, it is essential to know the difference between manual, semi-automatic, and automatic machines. Each method has features and advantages. This guide will help you understand such devices and decide which is best for your business.

Manual Bucket Printing Machine

Manual bucket printers operate manually. They are easy to use and generally less expensive than other types. They’re great if you have a low print volume and don’t need to print multiple buckets simultaneously.

Benefits of Manual Machines:

- Low cost of living

- It is easy to use

- Good for small orders

Drawbacks of Manual Machines:

- The print speed is slow

- A lot of hard work is required

- Not suitable for high-volume orders

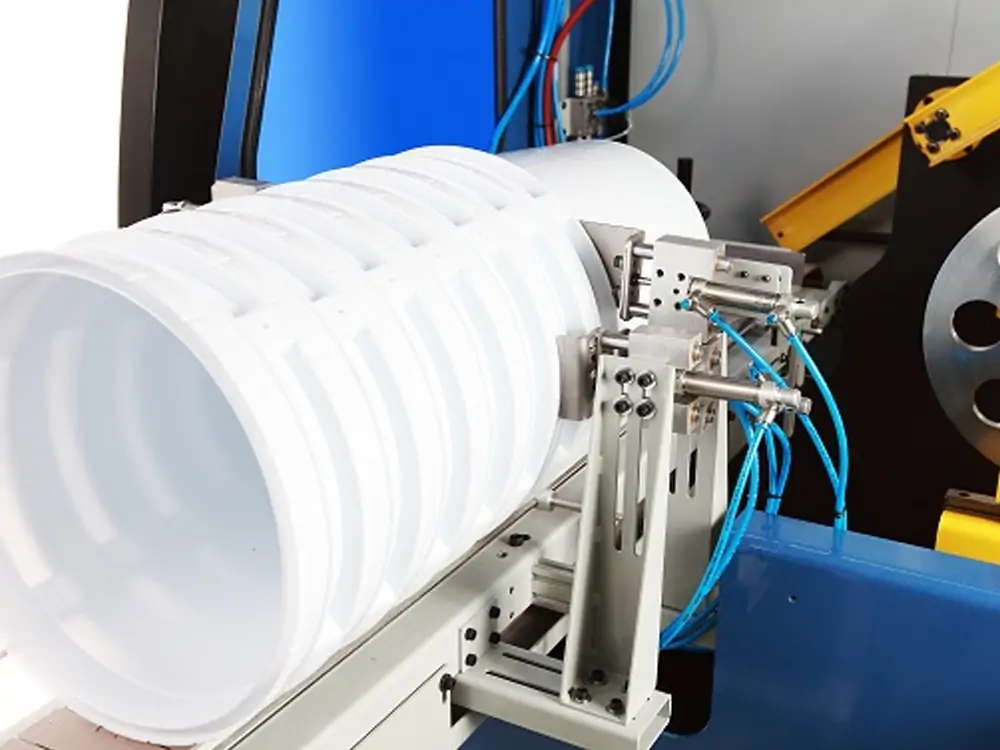

Semi-Automatic Bucket Printing Machines

Semi-automatic bucket printing machines combine manual and automatic features. They are faster than manual machines and require less effort to operate. You still need to load the buckets manually, but the printer was activated. This makes them ideal for mid-range projects.

Benefits of Semi-Automatic Machines:

- Faster than manual machines

- Easier to operate

- Suitable for medium-sized orders

Drawbacks of Semi-Automatic Machines:

- More expensive than manual machines

- Requires some manual labor

- Not as fast as automatic machines

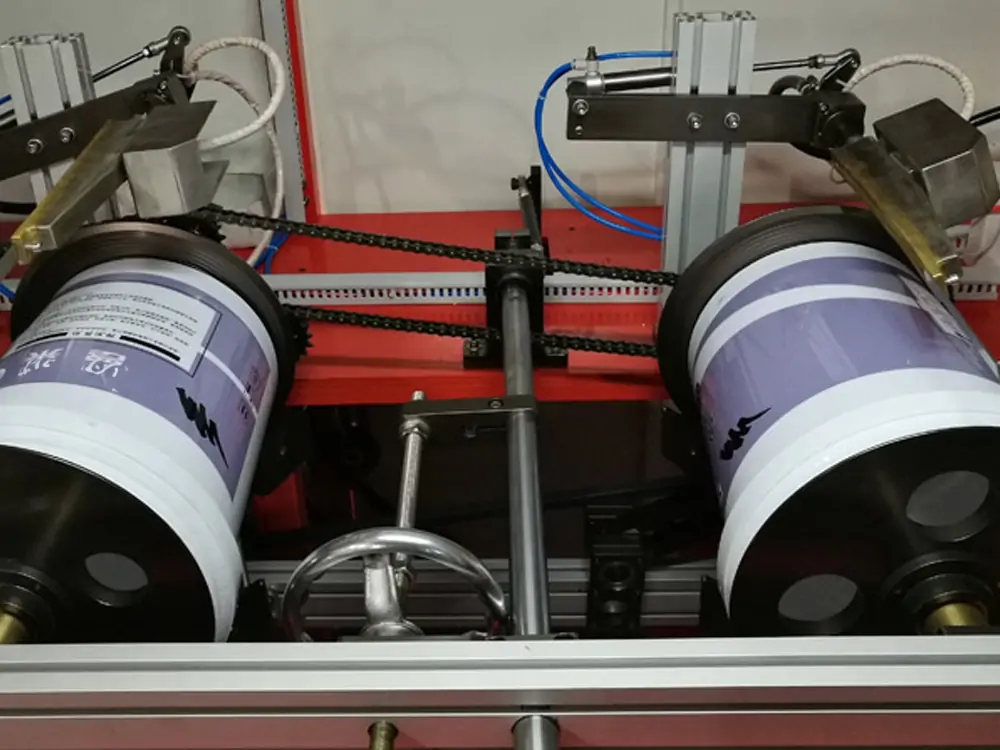

Automatic Bucket Printing Machines

Automatic bucket printing machines are fully automatic. They are the fastest and most efficient bucket printing machines. Automatic machines are ideal for large projects that require printing high-volume buckets quickly. You can set the print settings on automatic machines and let them handle all the work.

Benefits of Automatic Machines:

- Fastest printing speed

- Minimal labor required

- Ideal for high-volume orders

Drawbacks of Automatic Machines:

- Highest cost

- Requires more maintenance

- It can be complex to operate

Contact Information for Manufacturers or Distributors

Manufacturer’s Website

Start with the manufacturer’s official website. Most corporations have a “Contact Us” page where you can find their phone number, email address, and physical address. You can also find contact forms to get more information or ask questions.

Online Directories

Many online sites list manufacturers and distributors. Websites like ThomasNet, Yellow Pages, and Kompass can help you find company contact information. These directories often include search capabilities that help you find a particular producer or distributor.

Social Media

Many manufacturers and distributors have social media profiles. Platforms like LinkedIn, Facebook, and Twitter are notable places to locate contact information. You can message them without delay, or find links to their contact information on their profile pages.

Industry Associations

Knowing where to start when looking for information about manufacturers or distributors can be challenging. This guide will help you quickly and easily find the correct contact information.

Trade Shows and Events

Attending trade shows and industry events is an excellent way to meet producers and distributors. These events often provide contact information for attending companies, and you can also pick up business cards and brochures with contact information.

Business Cards

If you already have industry contacts, request business cards from recommended manufacturers or distributors. This is a reliable way to get contact information from trusted sources.

Search Engines

Using Google and other search engines can help you find hard-to-find information. Just list the manufacturer or distributor with keywords like “contact info” or “phone number.” This gives you direct access to the required records.

In conclusion:

Choosing the right bucket printing device is essential for achieving high-quality prints and improving your commercial operations. By understanding your printing goals, assessing your finances, researching each type of machine, evaluating printing quality, assessing speed and performance, considering ease of renovation, exploring customization options, and evaluating pricing and features, you can make an informed decision. Invest in the right bucket printing solution to increase productivity and consistency.